To identify fabric types, start with a burn test. Natural, animal, and synthetic fibers react differently to flame and leave unique ash residue. A water test is also helpful, as different fabrics have varying levels of absorbency. Look at the fabric’s density, texture, drape, and sheen too. The weight plays a role in the fabric’s thickness and durability. Each attribute offers vital clues about the fabric’s origin and composition. As you get acquainted with these methods and characteristics, your ability to accurately identify fabric types will sharply improve. More insights await you as you further examine this topic!

Key Takeaways

- Perform a burn test to observe the flame color, smell, and ash residue, which vary among different fabric types.

- Conduct a water absorbency test, as synthetic fibers typically repel water while natural fibers absorb it.

- Examine the fabric’s density, texture, drape, and sheen for visual and tactile identification clues.

- Consider the fabric’s weight, as heavier fabrics usually indicate higher durability and thickness.

- Identify animal fibers by their unique qualities, such as sustainability, biodegradability, and distinct textures.

Types of Fabrics

You’ll find that fabrics are broadly categorized into natural, animal, and synthetic fibers. Cotton and linen are natural fibers that come from plants, while wool and silk are animal fibers. Synthetic fibers, on the other hand, are chemically manufactured, examples of which include polyester and nylon.

Natural Fibers

Natural fibers like cotton, silk, wool, and linen have unique traits that can be identified through tests like the fabric burn test.

Animal Fibers

Fibers like wool, silk, and alpaca are widely used in fabric production because of their special qualities. They provide comfort, durability, and a unique look. These animal fibers, sustainable and biodegradable, are prized in fabric production for their unique textures and qualities.

Synthetic Fibers

Synthetic fibers such as polyester, nylon, acrylic, rayon, and acetate are important in the fabric industry because they have special qualities. To identify these synthetic fibers, you can conduct a burn test, observing how the fabric reacts to flame. This knowledge arms you to choose the right fabrics for your projects.

Burn Test for Identifying Fabric

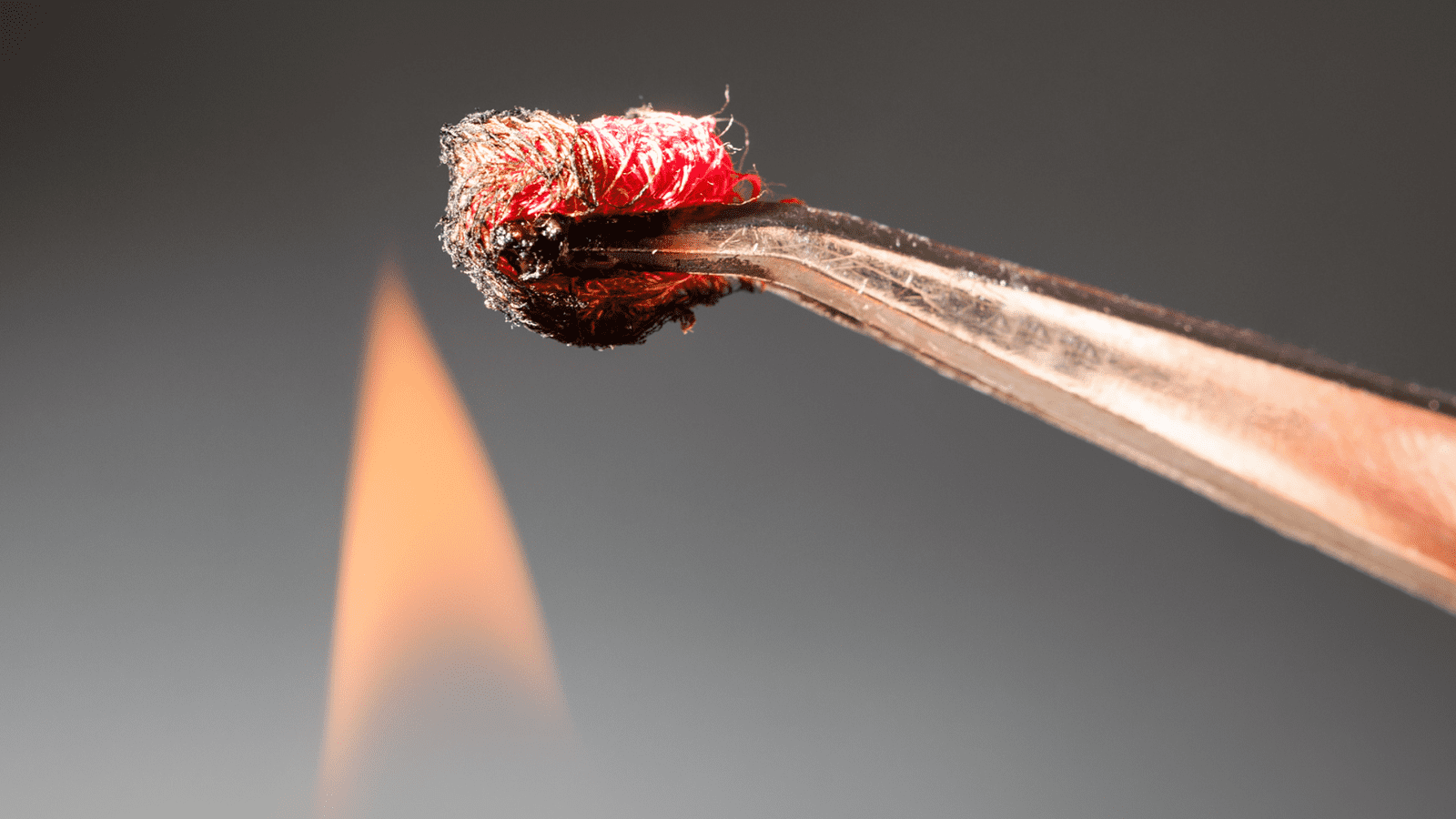

When identifying fabrics, the burn test can be your go-to method. First, you’ll need to cut a small fabric sample and hold it with a pair of tweezers. Carefully light the sample with a lighter and observe the flame’s color, size, and shape, as well as the smoke and the ash’s texture and color.

Step 1: Cut a small fabric sample and hold it with a pair of tweezers.

To begin the fabric burn test, carefully cut a small fabric sample and hold it securely using tweezers. This process will help you identify the fiber content. Don’t cut a large piece; a small snippet is sufficient. Make sure you’re not damaging the fabric’s structure or design. Please stay safe and protect your fingers away from the flame.

Step 2: Ignite the fabric sample with a lighter.

Now, carefully ignite the fabric sample using a lighter, paying close attention to how the material reacts to the flame. If it’s a natural fiber like cotton, it’ll burn steadily, potentially leaving an ash residue. Synthetic fibers, such as polyester, will behave differently. They’ll likely melt and sputter, giving off specific smells. This is a simple, yet effective way to distinguish between natural and synthetic fabric materials.

Step 3: Observe the color, size and shape of flame and the features of smoke.

Observe the color, size, and shape of the flame and the characteristics of the smoke when setting the fabric sample on fire. The behavior of the flame and the color of the smoke can provide valuable insights into the fabric types.

Step 4: Examine the color and texture of the ash.

After putting out the flame, check the color and texture of the ash left by the burned fabric. These will show what type of fabric it is. The way fabric burns and the ash residue it produces can tell you a lot. This step is critical in the fabric identification process. So, don’t rush this part – carefully examine the ash, noting its color and texture. These details will assist you in accurately identifying the material.

Drawing Conclusions from Fabric Burn Test

By conducting a fabric burn test, you can gather key information that helps identify the fabric type. If the fabric burns easily and leaves powdery ashes, it’s likely a natural fiber. Animal fibers resist ignition, produce a burning hair smell, and leave bead-like residue. Synthetic fibers, on the other hand, curl away and melt.

Natural fibers are easy to burn and smell like burning paper. They leave powdery ashes.

During a fabric burn test, you will find that natural fibers like cotton and linen quickly catch fire and produce a smell similar to burning paper. This smell is a clear indication of their natural origin. It’s this distinct odor that sets the burning fabric apart from its synthetic counterparts.

Additionally, the ashes left behind from these natural fibers are noticeably powdery, unlike the residue from synthetics or blends. The burning speed, the paper-like smell, and powdery ashes are all clear indicators that you’re dealing with natural fibers.

Animal fibers are hard to ignite and smell like burning hair. They leave a bead-like residue.

Compared to natural fibers, animal fibers such as wool are more difficult to set on fire. They give off an odor similar to burning hair and leave a bead-like residue when burned. This distinctive smell and unusual residue can be your key to identifying such fibers.

When you perform a burn test, pay close attention to the scent and the post-burn remnants. If you detect a burning hair smell and observe a bead-like residue, it’s highly likely you’re dealing with animal fibers.

The residue’s characteristics, specifically its brittle nature and dark color, further confirm this. So, don’t be quick to disregard these signs. The results are not random, but they indicate the presence of wool or other animal fibers in your fabric.

Synthetic fibers curl away and melt when burning.

Polyester, nylon, and acrylic are synthetic fibers known for their behavior when exposed to fire. The curls gently disperse and dissolve, providing crucial clues for accurate identification. Carry out a simple burn test and observe their behavior.

When you light a small swatch, you’ll notice rather than burning steadily like natural fibers, synthetics tend to sputter. Instead of ash, they leave a hard, bead-like residue. Moreover, they emit a distinct, often acrid smell.

Water Test for Identifying Fabric

Let’s move on to the water test for identifying fabrics. First, you’ll need to cut a small fabric sample and place it on a flat surface. Then prepare a glass of water. After applying a small drop of water to the fabric, you’ll observe how the water reacts – does it bead up, spread out, or absorb quickly?

Step 1: Cut a small fabric sample and put it on the flat surface.

First cut a small sample of fabric and lay it on a flat surface for the water test. This is crucial as it initiates the absorbency test, a proven way to distinguish between natural and synthetic fibers.

Step 2: Apply a small drop of water to the fabric.

Apply a small drop of water to the fabric’s surface to perform the water test. This test is a simple yet effective method to distinguish between natural and synthetic fibers based on their absorbency.

Step 3: Take a look at how the water reacts.

Now, closely observe how the water interacts with your fabric sample. This water test can be revealing in distinguishing natural fibers from synthetic fibers.

If the water beads up on the fabric’s surface, you’re likely dealing with synthetic fibers such as polyester. These fibers don’t absorb water readily; instead, they repel it.

If the water is absorbed quickly and the fabric becomes damp, you probably have natural fibers like cotton. These fibers absorb water easily.

Step 4: Blot the water after a few seconds, and observe whether there is any water stain residue.

After waiting a few seconds for the water to soak into the fabric, blot it and check carefully for any remaining watermarks. It allows you to assess the fabric’s absorbency, an essential characteristic that can differ greatly among various fabrics.

If the fabric has good absorbency, there should be minimal to no water stain residue. It is a simple and effective method that gives you valuable insights into the fabric’s composition. So, don’t rush this step. Take your time to observe and analyze the results carefully.

Drawing Conclusions from Fabric Water Test

From the water test, you can make critical deductions about fabric types. For instance, if the material absorbs water quickly, it’s likely cotton, whereas a waterproof response indicates polyester.

Observing slow absorption with no residual droplets hints at silk, while slow absorption accompanied by water spots suggests wool.

Cotton absorbs water quickly.

Cotton is known for its ability to absorb water quickly, making it feel damp to the touch. This fast absorption rate is a key trait in cotton fabric identification. When you expose cotton to water, it acts like a sponge, soaking up liquid quickly.

Polyester is waterproof.

Cotton absorbs water, while polyester is waterproof. When you conduct a water test on polyester, you’ll notice that it doesn’t absorb water. The fabric will repel the liquid, leaving droplets beading up on its surface. This behavior is a clear indication of polyester’s hydrophobic nature, making it a waterproof fabric. This attribute is important in many applications, like outdoor and activewear clothing that needs to be durable and protect against moisture.

Silk absorbs water slowly without any residual water droplets.

Silk absorbs water slowly and doesn’t leave any droplets, which is unique to this fabric type. This slow absorption rate is a vital characteristic in the identification of silk. When performing a water test, you’ll see that silk absorbs it gradually, exhibiting no leftover droplets. This unique feature is key in differentiating it from other fabrics.

Wool absorbs water slowly and leaves water spots.

Wool absorbs water slowly, resulting in visible water spots on the fabric’s surface. This characteristic can be a valuable clue in identifying wool among other fabric types. When you conduct a water test, you’ll observe this unique behavior of wool. It’s not just about the water spots; they tell you a lot about the fiber composition of the fabric. Wool’s interaction with water, its slow absorption rate, and the resulting water spots help differentiate it from other materials.

Physical Characteristics of Fabric Identification

When identifying fabrics, you’ll find certain physical characteristics particularly useful. Focus on the fabric’s weight, texture, drape, and sheen, as these are key indicators of a fabric’s type.

Fabric Weight

When identifying fabric types, considering the fabric’s weight in grams per square meter (GSM) is crucial. Fabrics with lower GSM are lighter and less dense, while fabrics with higher GSM are heavier and denser, making them thicker and more durable.

Understanding fabric weight is important for choosing the right fabric. It helps balance functionality and aesthetics, leading to a satisfactory end product.

Texture

Ever wondered how the physical characteristics of a fabric, particularly its texture, can aid in its identification?

The texture of a fabric reveals a lot about its type. By simply touching, you can discern whether a fabric has been made from natural fibers or synthetic ones. Natural fibers like cotton, wool, silk, and linen usually have a soft texture. Synthetic fibers like polyester, nylon, and acrylic may resemble natural fibers, but they feel distinct when touched.

Drape

Texture and drape of fabric give insights into its type and quality. Drape refers to the way in which fabric gracefully hangs or cascades when it is draped. It indicates the fabric’s weight, flexibility, and fluidity.

Fabrics with good drape flow smoothly, adding grace to the silhouette of a garment. For instance, lightweight fabrics like silk exhibit excellent drape, enhancing the fluidity of a design. On the other hand, heavy fabrics like denim have less drape, resulting in a stiffer silhouette.

Sheen

The sheen of a fabric is important for identifying different types of fabrics. The sheen varies based on the fiber content and finishing processes.

Silk and satin fabrics have a smooth texture and reflect a lot of light, which makes them feel luxurious. Synthetic fabrics, such as polyester, can also be engineered to have a high sheen, mimicking the appearance of silk.

Conclusion

So, there you have it! Now you’re equipped with the know-how to identify different fabric types. You can determine the type of fabric by doing the burn test, the water test, or by observing its physical characteristics.

Learn more about fabric knowledge at Longan Craft Blog, and dive into the fabric world with Longancraft!